When Bonnie Moore, VP of development and innovation for the CREDC, asked the food processing industry leaders what their highest priorities were for staying globally competitive and growing in Clark County, they told her that energy costs were the number one issue. Rather than trying to solve each company’s individual challenges, CREDC and Clark PUD decided to form a consortium to help both larger and smaller scale companies qualify for big programs.

Through the Columbia River Economic Development Council’s (CREDC) adoption of the Clark County Economic Development Strategic Plan in 2011, Agricultural Processing, which includes food processing, was identified as an industry in Clark County that needed to be nurtured. Though there are only a handful of companies, food processing has been in the Pacific Northwest for 100 years, is the third largest manufacturing employer with more than 280,000 workers and generates $42.5 billion in revenue.

Specifically focusing on the food processing industry’s energy costs, Clark PUD and CREDC partnered with Bonneville Power Association (BPA) Energy Smart Industrial, Oregon State University’s Industrial Assessment Center, Impact Washington, Envision Controls Engineering, WSU Industrial Energy Projects and Northwest Food Processors Association, and came up with the consortium concept, combining the kilowatt hours of small and large-scale companies within an industry to access a grant.

“Everyone expects these programs to benefit big businesses,” said Moore. “But, when we put this consortium together, combining big and small businesses, it allowed the small businesses to be eligible for programs they wouldn’t otherwise be eligible for. By combining the total kilowatt hour goals, we were able to convince BHP Billiton to award a grant to us.”

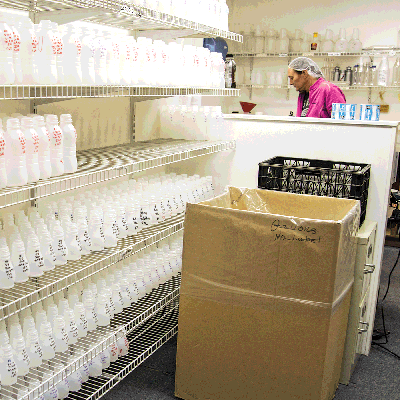

Frito-Lay Inc., Neil Jones Food Company, Great Western Malting, Northwest Natural Products (now owned by Church & Dwight Co. Inc.), Firestone Pacific Foods, Tetra Pak and Andersen Dairy/Andersen Plastics were the seven food processing companies with nine plants chosen for the Clark County Food Processors Energy Project Consortium, a three-year program.

“Smaller companies don’t use as much energy, so their savings aren’t as great. But they have the same problems and needs the big companies do,” Moore added.

The goal of the consortium is to share financial and technical resources and operational knowledge to solidify the industry into a cohesive cluster and share one energy project manager between them. Other benefits to the food processors include capital asset incentives, technical energy assessments and innovation engineering training/consulting.

According to the consortium’s scope of work, “The Clark PUD Energy Smart Industrial (ESI) Co-funded Energy Project Manager (EPM) Program offers funding to bring outside technical resources to participating companies and work on energy cost reduction for electricity, natural gas, water and environmental sustainability.”

“As far as the EPM, it is part of what’s called the ESI Program, where we work with BPA to offer industrial customers certain services,” explained Larry Blaufus, senior manager of energy technologies and services at Clark PUD. “In this case, it’s a project manager to be onsite and be able to look for projects, help implement projects, have some influence with management to get capitol for projects and normally this is done one company at a time, and maybe a hospital will do it for all of their hospitals, like Legacy or PeaceHealth.”

It differs in this case, he said, because the EPM, Tim McMenamin, is shared between seven companies.

“There’s usually the hurdle of saving one million kilowatt hours to be able to justify paying for this person, so what they do in this case is take it and spread that out across all eight and treat it like one company,” said Blaufus.

The consortium also creates an industry cluster that enables large and small companies to treat each other as an operational resource on how they complete their projects internally.

In eight months, the program has identified 40 energy projects and has helped Great Western Malting and Frito-Lay complete five of those projects.

“Already we have helped them save seven million gallons of water each year and two million kilowatt hours of electricity usage, which frees up the grid and keeps the costs manageable for Clark PUD. We helped them save $200,000 in bottom line cost savings,” noted Moore.

“The nice thing about this program,” added Blaufus, “is that, even though it’s paid by electrical savings, the companies have the ability to use the resources, as long as the hours are covered – gas, water and anything else that’s of a utility nature, but the payment for the program has to come directly from electric energy savings.”

Robert Seggewiss, plant manager for Great Western Malting said that because of the findings and incentives of the program they purchased higher efficiency motors, improved their compressor and relocated equipment.

“They gave us incentive with regards indirectly to funding, to a team coming in and facilitating the improvements, to lean management and looking at the Kaizen approach, which was quite an effective approach. We are going to use it in our other work, not only with utilities but with safety and quality, so there’s a bit of a spin-off,” said Seggewiss.

Going forward, Blaufus and Moore said they see this type of program transferring to other industries, like high tech and metals. Moore noted that they have already leveraged this model to help apply for another energy grant in the metals industry for the Tri-County/Greater Portland area.